Thank you, Ray, I noticed the same thing. Most nickels (and probably any other modern coin) come from the mint with a fairly tight range of diameters, with an occasional flyer that's way out there. If the collet is engineered correctly, it'll close. It's not ideal if it needs to pinch down on something significantly smaller, but it'll still work.

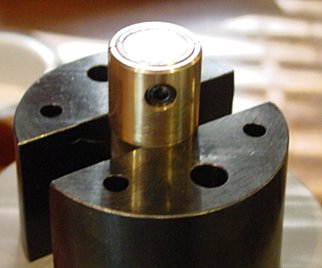

Given the input so far, I cranked out another, from Bronze.

This one I split both sides, used a larger hex screw, and milled 4 flats on the base so that it'll secure nicely in any engraver's vise.

As a fun test, I installed a modern nickel and put it in the lathe. I could almost hear poor Mr. Jefferson shrieking "Nooo-ooo-oo" as I erased him from the field.

The collet held up nicely. This one I bored out what I'd call sloppy, but there's more than enough clamping action to secure the coin. Only a real acid test will tell, but I'm confident - you'd have to apply a cold chisel and a carpenter's hammer to move this coin with the screw set.

Finally, how it'd look in a vise:

I have no desire to bore people on an engraving site with a lot of machining stuff. I genuinely want to contribute in some small way, and maybe this sort of thing might help some people having trouble with workholding. Steve L., please pull the plug anytime. I'm not here to hawk stuff, and I rarely machine for $$; I'm here to learn how to engrave from the masters of the art.